The implementation of SAP solutions and access to a complete set of source and result data allows improving the operation of the entire enterprise, which translates into better sales results. For this to happen, it is worth considering choosing the right partner who will tell you what aspects of the automotive industry are worth paying attention to.

Everything in one place

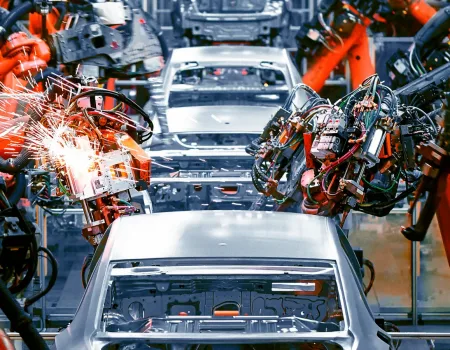

Modules popular in the automotive industry, producing parts delivered for final assembly include SD (Sales and Distribution) and its part LE-TRA (Logistics Execution – Transportation), MM (Material Management), WM (Warehouse Management), and PP (Production Planning), often integrated with SAP PM (Plant Maintenance). At each stage of the production plant’s operation, data on manufactured goods process inside modules.

Data magic

The MM module records purchases of goods or raw materials. As Patryk Chlebda, Senior Consultant in the Logistics and Automotive Team states: “MM is one of the basic modules, dedicated to companies for which inventory is important, e.g. production or those dealing with understood trade. The module handles purchases but also managing receipts, releases, and material consumption.”

All SAP logistic modules integrate with the MM module, which facilitates the creation of a coherent and effective business development strategy. In the PP module stage, raw goods, in other words, raw materials, are turned into a product. And the SD module records their sales to customers. In turn, the PM module supports the management of maintenance, machine park, tool room, and infrastructure owned by the company. Often, companies operating in the “just-in-time” model also use LE-TRA functionality.

On the occasion of the functioning of the modules, costs related to each undertaken activity are booked. At all stages of contact with the goods, the values are posted on the General Ledger accounts and in controlled facilities, which are automatically made available in the FI/CO module (Financial Accounting and Controlling) and then analyzed.

As you can see, by following this path, a production company, having access to complete data, receives a financial and controlling result. The company’s management can find out how much the organization has cost for each stage. Thanks to this, it is possible to or show the processes within which improvement and optimization should be sought.

Individual approach to the topic

SAP solutions, although they operate in many industries, can be tailored to specific areas of the economy. In the case of automotive and even narrower specialization, i.e. the production of vehicle components, the following issues are very important: electronic data interchange EDI, thanks to which the ERP system of the component supplier integrates with the customer’s system; the need to plan production packaging and quality management or the possibility of modelling production processes, reducing waste and eliminating unnecessary operations and procedures during production.

Support for production systems is also important. Typical automotive companies that deliver products for final assembly in the “just-in-time” model operate within one or two shifts. But, the factory’s working hours do not coincide with the hours of logistics activities and deliveries to customers, which usually takes place at night. In the context of the company’s operational activities, these are not standard working hours but remain crucial for the end customer. This is an important aspect when choosing the support for the system and necessary to decide its scope. In this case, a 24/5 or 24/7 model seems reasonable.

The partner selected to implement, improve, and maintain the system should be close to the client’s needs. He should understand its premises and know the vision of the company’s development. At Hicron, we believe in the principle of caring for long-term business relationships. That is why we take the position of a trusted advisor. We can guide our clients, including those from such specific industries as component manufacturers, from the moment of searching for an optimization method, to its implementation and maintenance. In line with Hicron’s slogan: VisiON Architect. SolutiON Maker.