Problem

Which transaction is used to create a new material in the mm SAP module?

Step-by-step SAP instructions

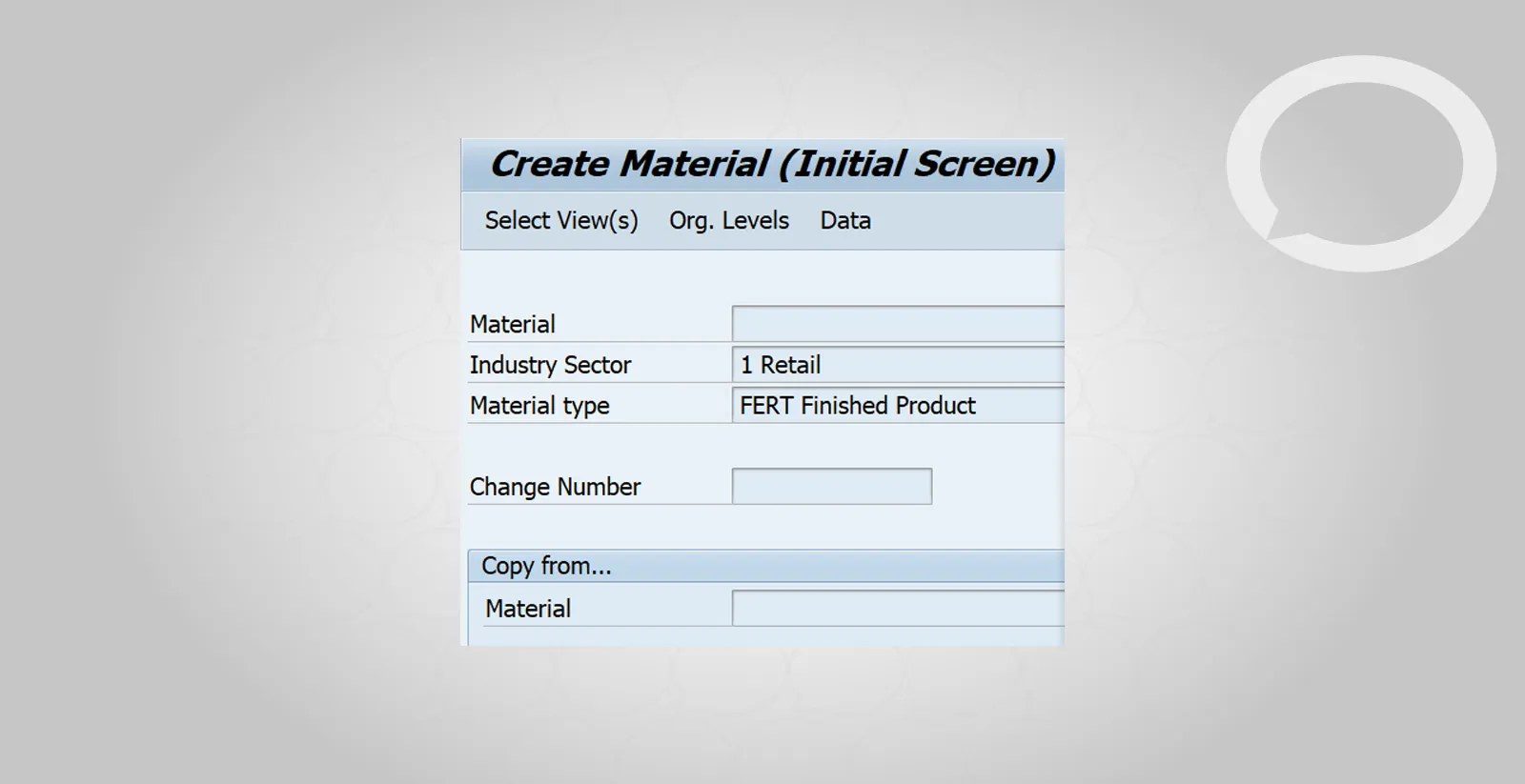

1. To create a new material in the mm module, we use transaction MM01.

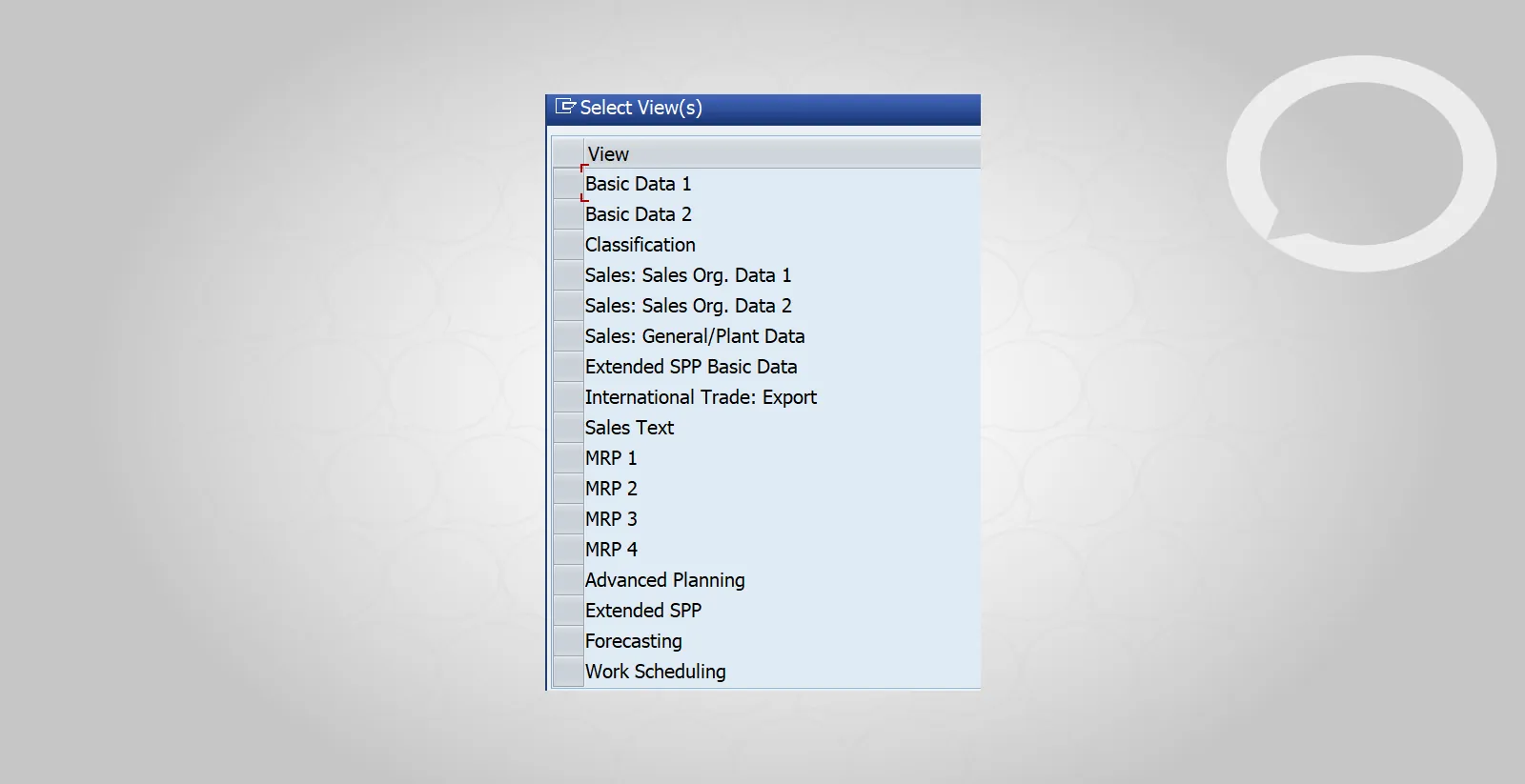

When executing MM01 transactions, you will notice that there are views (tabs) depending on the function they perform. The information contained therein is intended for the appropriate department in a company. For example, the material master record contains information about:

- Accounting

- Material requirements planning and material availability controlling

- Purchasing

- Production

- Storage

- Forecasts and previous consumption data

- Sales and distribution

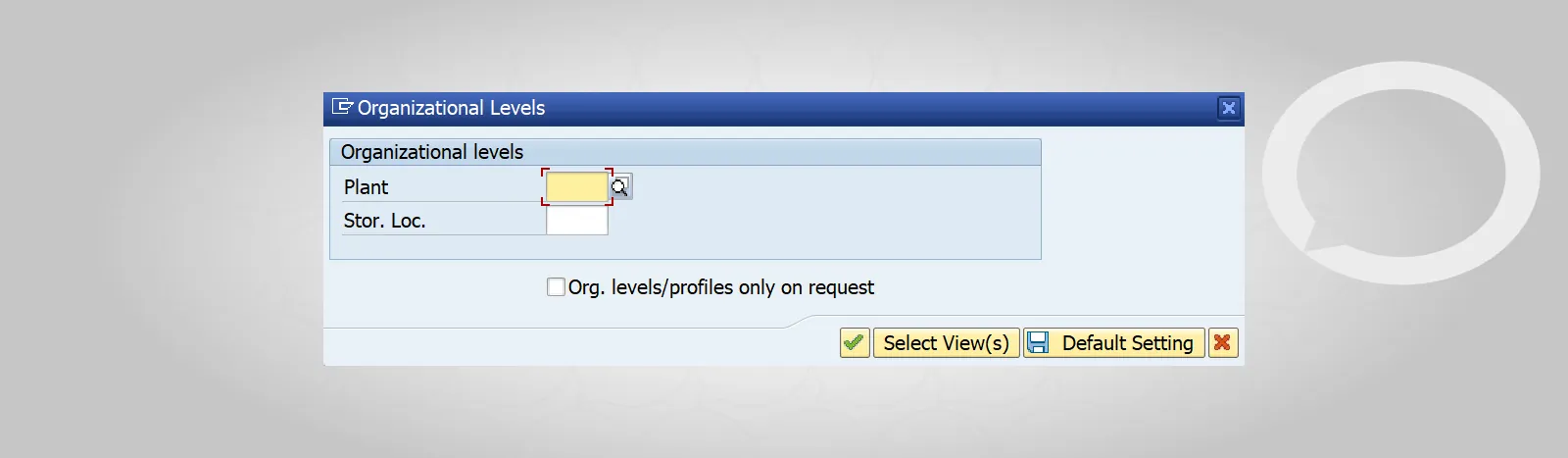

2. In transaction MM01/MM02 (change), there is also an organizational dimension to data entry.

This means that when you create/change a material master record, you must specify the organizational level for which you want to change the data. You can do this for any level, e.g. plant level, storage location level, purchasing department level, etc.

When you create a material master record, you must specify the plant, storage location, or other element of the organizational structure for which the material is being created.

3. We can create or extend a material master data record (called Material Master) (in transaction MM01).

4. When creating a material master record, the question arises: what number to choose for the newly created material?

However, you should be aware that as an end user, you may not have the appropriate rights to choose the numbering freely. This is because the method of defining number ranges for created materials has been defined by the system administrator. The SAP system allows you to define two numbering methods: external and internal. You can define the number yourself only if the company uses the external numbering method; otherwise, it means that the company uses the internal numbering method, and the number is automatically assigned as the next one from a previously defined range. In the latter case, you will be given the number only after the material is created.

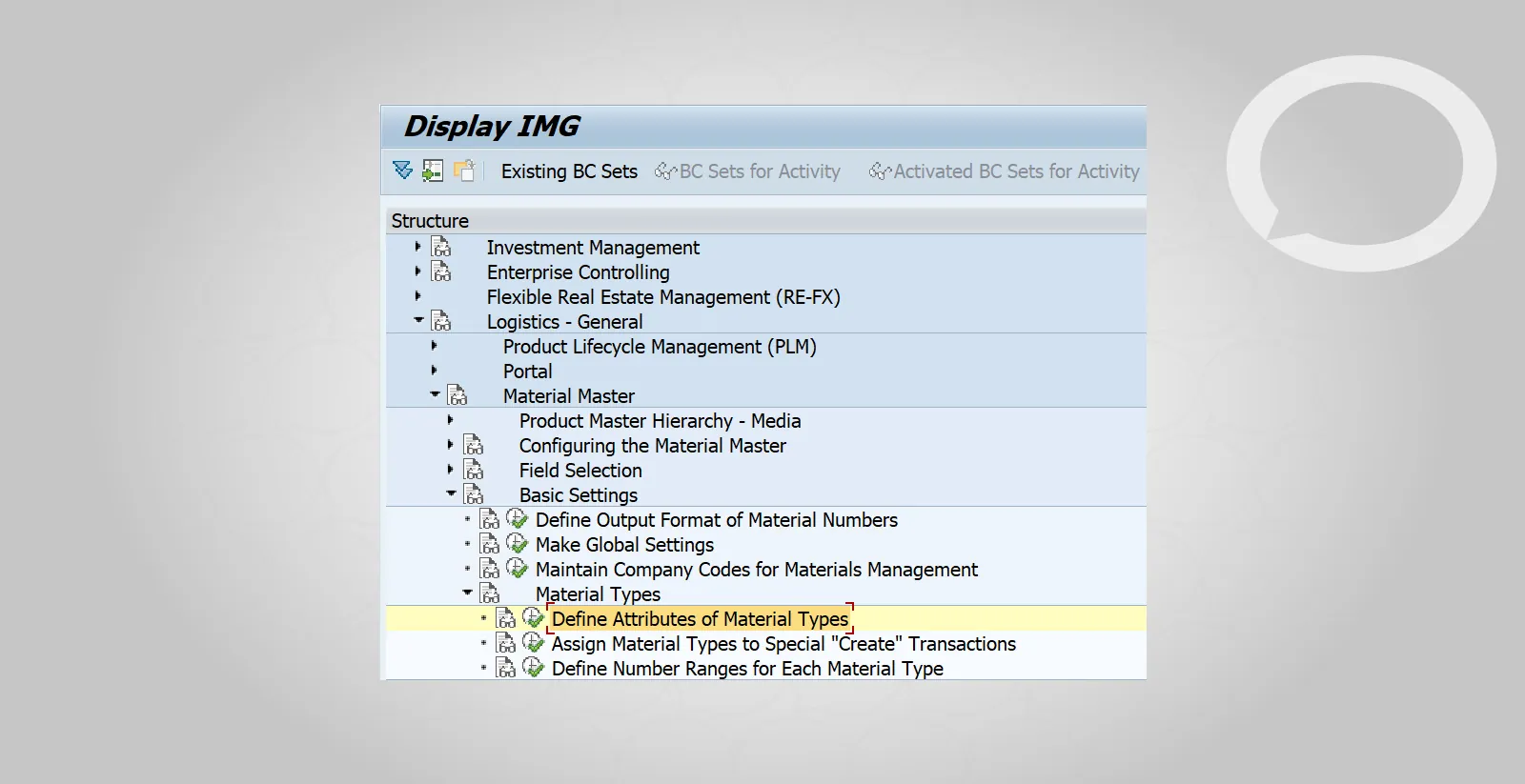

The graphic below shows an example of how to define a number in the configuration guide (SPRO).

5. Menu path for configuring material number ranges.

The company can use a different numbering method for selected material types and a different one for other material types, i.e. packaging materials, finished products, semi-finished products, and so on.

6. You select the type of material at the stage of its creation, i.e. in transaction MM01.

7. In transaction MMAM, you can change the material type for a material that has already been created.