Automotive supply chain – inventory management with SAP Automotive

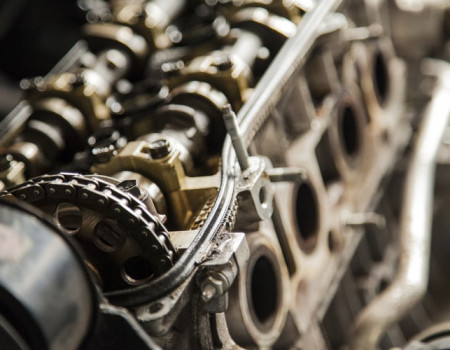

Effective inventory management requires tracking thousands of components, from small parts to entire assembly modules. SAP Automotive supports entrepreneurs in this area. The system is equipped with advanced monitoring and optimization features that enable real-time inventory tracking, eliminating the risk of overstocking or product shortages.

An efficiently managed automotive supply chain is the first step to market success. SAP Automotive makes it much easier to accurately predict component demand. The implementation of the tool reduces storage costs and eliminates production downtimes.

Production planning with an ERP system – the supply chain and optimal use of resources

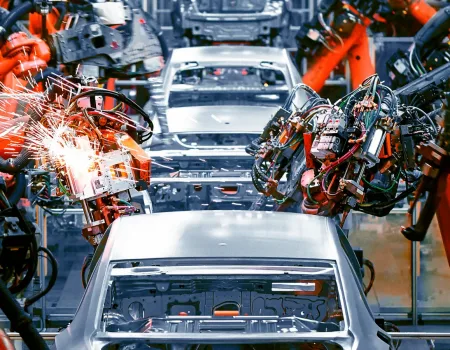

Fluctuating order volumes and seasonal production variations inevitably impact the efficiency of supply chain management in the automotive industry. Integrating components from multiple suppliers can also prove challenging. SAP Automotive helps overcome these difficulties by facilitating the optimal use of resources.

The system provides advanced production planning tools that streamline the automotive supply chain. It enables the creation of accurate schedules that take into account available materials, individual delivery dates, production capacity, and customer orders. As a result, they are completed faster and at lower operating costs.

Automotive supply chain – supplier integration

Collaboration with suppliers is an important part of supply chain management. SAP Automotive supports integration with these partner at every stage – from ordering and monitoring delivery progress to quality control of delivered components. It is a digital platform for real-time data exchange. Its advanced capabilities enable automotive companies to respond quickly to potential delivery delays or other issues.

How else does SAP Automotive affect the supply chain? ERP supports order automation and synchronization of the production schedule with JIT (Just-In-Time) deliveries. For entrepreneurs, this means better coordination of activities with multiple suppliers and increased transparency of collaboration.

Data analysis and the supply chain – ERP for informed decisions

Collecting, processing, and analyzing vast amounts of information from across the supply chain is time-consuming and difficult. Implementing an advanced ERP system such as SAP Automotive makes this task easier for automotive companies by providing them with reliable tools for data analysis. The platform enables rapid identification of potential issues, anticipation of future needs, industry trend forecasting, and informed business decision-making.

There is no doubt that SAP Automotive has an impact on the automotive supply chain, and its implementation brings numerous benefits to businesses. These include greater efficiency through improved production processes and better collaboration with suppliers. SAP Automotive also provides greater flexibility in adapting to changing market conditions, improves planning, optimizes scheduling, and enables waste elimination.