What is production process automation?

In every production company, sooner or later, there is a need to establish the sequence of production activities. For smaller facilities, this need may arise later, while larger ones cannot begin work without a specific, detailed, and well-thought-out strategy.

Therefore, it is very important to implement production process automation as soon as possible, so that each stage of production is carried out correctly. This helps avoid mistakes, overproduction, understocked warehouses, downtime, or even problems related to understaffing in the organization.

What is production process automation?

This term is used to describe the use of technologies and systems that allow production tasks to be performed with minimal or no human involvement. The use of such production organization is aimed at ensuring maximum safety at each of its stages, the highest quality of products, as well as increasing the effectiveness, efficiency, and precision of the production line. Such solutions include: sensors, artificial intelligence, industrial robots, and numerically controlled machines.

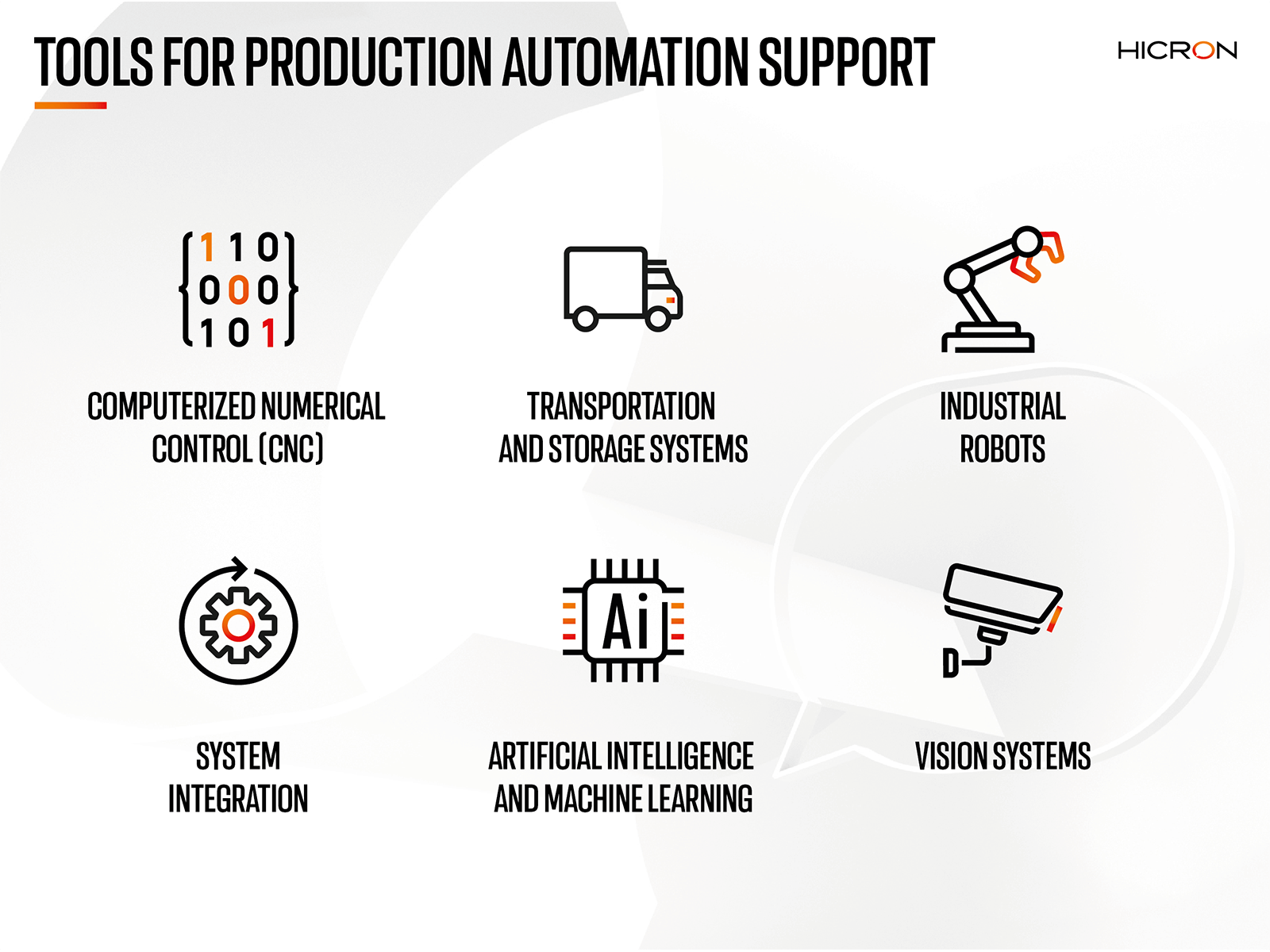

Tools for production automation support

This strategy may include the following technologies:

- computerized numerical control (CNC) – this solution makes it possible to control production machines using numerical codes, allowing precise and repeatable processing of materials; examples of machines whose work can be programmed in this way are lathes, milling machines, welding machines and laser cutters;

- transportation and storage systems – these include conveyors, automated guided vehicles (AGVs), and automated machines that safely and efficiently move products between production stages;

- industrial robots – machines that are properly programmed to perform physical tasks that are monotonous (painting, welding), time-consuming (screwing), or require a lot of physical strength (lifting, moving heavy objects);

- system integration – as the name suggests, it consists in connecting systems (e.g. ERP) in such a way that they are fully synchronized and work together as efficiently as possible;

- artificial intelligence and machine learning – this technology makes it possible to accurately analyze data, optimize all areas of production, and predict and prevent failures;

- vision systems – this technology uses cameras and sophisticated algorithms to detect, monitor, and inspect production processes; when properly applied, it can help control product quality, detect and prevent defects, and maintain compliance with accepted standards.

How to safely automate production processes in a company?

In order to improve production in an enterprise, it is necessary to prepare it for such an undertaking in advance. Here are the elements that go into developing an appropriate strategy:

Risk analysis and assessment

It involves identifying the potential risks associated with the planned automation and assessing the impact of different types of risks on the operation of the company, especially on the production department and employees.

The right technology

Each tool has its own unique functionalities and capabilities. Only when they work well together will they support the business in its day-to-day operations. Choosing the right system depends on the size and complexity of the company, the characteristics of its teams, and its production schedules. Choosing the appropriate technology is crucial for the entire implementation.

Legal conditions and standards

This refers to a thorough inspection of the company to ensure that it meets all necessary legal requirements, safety standards for machinery, the production line, and the entire production process. This inspection includes compliance with EU directives and local regulations relating to occupational and machine safety.

Preparation of the implementation plan

The right strategy for automating production processes also includes a detailed definition of the various steps of its implementation. At this stage, it is important to establish goals, a schedule, involve specific employees, assign responsibilities, specify the resources needed to complete the project, estimate costs, and identify benefits.

Testing and optimization

Before deciding on a particular solution, it is necessary to test it in advance to avoid complications. Such trials are conducted using existing data and scenarios. At this stage, it is important to monitor the operation of the system, collect data and feedback from its users. This makes it possible to tailor the solution to the needs of the company, ultimately improving productivity and efficiency.

Team training

Before full implementation, it is a good idea to prepare employees for the change. Their proper training before, during, and after implementation (including regular training on the changing functionality of the tool) ensures a more secure implementation.

Implementation and control

If the managers have not yet decided to seek help, this is the time to look for an implementation partner. They will support the company in this complex task, allowing it to maintain business continuity and a stable position on the market. Once a tool has been properly introduced into the organization’s environment, it is extremely important to inspect it on a regular basis. This will help keep the system operational and minimize any malfunctions or failures.

Maintaining the highest level of quality

This stage is the last part of the implementation of production process automation. It is related to maintaining the efficiency of the system, its constant updates, improvements, and expansion of its functions. At this point, it is worth using the support of the implementation partner who installed and deployed the tool. They are the ones who know it best, are familiar with the specifics of the organization, and will help maintain the system at a level that is satisfactory and produces the desired results.

Help from the right systems = top quality automation

Among the solutions available on the market, it is difficult to find one that will be the best for a given organization. The issue of advanced, modern technologies may be a signpost in the search. Their choice may prove to be the ideal solution for entrepreneurs looking for tools tailored to the needs of their users and the constantly changing needs of the company and business. Only the most up-to-date tools can ensure comprehensive automation of production processes.

For companies looking for this kind of support, cloud systems that store and process vast amounts of data and allow it to be shared in a secure and controlled manner within company space will work well. What is more, they integrate information obtained from different parts of the organization: HR, finance, analytics, sales, purchasing, logistics, or production. They also allow essential routine operations to be carried out automatically.

SAP S/4HANA is such an ERP system, equipped with all the functionalities to support all types of production. It has modules that also provide the ability to monitor production conditions in real time. This helps define trends, risks, analyze production data, and thus optimize processes, which means that production can be adapted to changing conditions on an ongoing basis.

All these functionalities of the modern SAP S/4HANA system are complemented by its mobility. It allows users to log in to the tool at any time and from any location with Internet access. This ensures smooth operation and maximum data currency. In this case, the benefit is also the improved communication between teams that this type of technology provides. Employees can access important data more quickly and easily, accelerating document circulation as well as speeding up and improving production.

Among the many advantages of S/4HANA, one should not forget the possibility of its integration with other systems, not only those created by SAP. It is compatible with other technologies used in the operation of businesses, such as: inventory and enterprise resource control tools, logistics, human resources, payroll, marketing, and sales systems, e-commerce websites, service platforms, and systems that monitor the efficiency of production machinery and those that ensure quality.

Implementing production process automation with SAP S/4HANA gives companies the security and freedom to execute projects tailored to their specific characteristics.

Implementing S/4HANA with Hicron for your organization’s success

As an SAP implementation partner with more than fifteen years of experience, we understand the realities that companies face, not just when it comes to automating production processes. Our knowledge of business and its needs has allowed us to develop proven strategies and customize them to meet individual client needs. Looking for help implementing a cloud ERP system? Or maybe you need an advisor to take care of the maintenance and security of the systems you already have? Contact Hicron experts who will find a solution that meets your expectations!