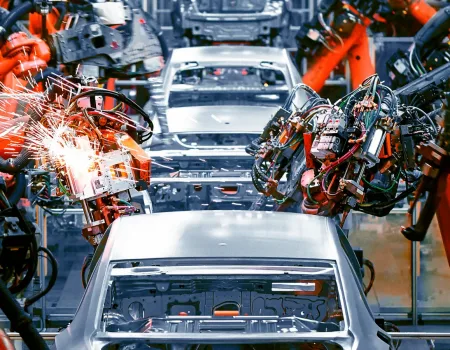

Serial, unit or mass production, make to stock or make to order, process handling according to the principle of first in first out, last in first out – these are the basic concepts that can reflect in most ERP systems. Experienced in designing innovative visions and creating efficient solutions, we present the most important elements that must be included in the ERP system of a manufacturing company for Automotive.

The automotive industry, which brings together producers of components for vehicle construction, represents this type of company that has particularly developed requirements in the field of logistics support. But the flexibility of the solution and the ability to adapt it to different types of production is not enough. When choosing a partner to implement a management solution for a production company for the automotive industry, you should pay attention to several very important aspects related to the specificity of these companies’ operations.

See also:

Advantages and use of SAP ERP in manufacturing companies in the automotive industry

Production planning in the automotive production company

Electronic data interchange – EDI systems

Manufacturers of automotive components usually have very large and demanding companies as customers – international giants of the automotive industry, who dictate the terms of cooperation. The business process related to placing orders most often takes place through the individual communication portal of the vehicle manufacturer. The component manufacturer’s ERP system has to adapt to the form imposed by the giant.

Receiving orders, sending invoices and other documentation, handling notifications and complaints should be such as not to complicate or extend the sales and production cycle. Instead, it is to increase the comfort of work and ensure the greatest transparency of the documentation flow. The automotive supplier’s ERP system must integrate with the supplier’s system through a solution for electronic EDI data exchange.

When choosing an ERP system for an Automotive manufacturing company, you should pay attention to whether it has its EDI solutions built-in and if so – what. If not – does it allow integration with external EDI systems, supporting transactions by EDI industry standards – incl. VDA, Odette, EDIFACT, and ANSI X.12.

The possibility of implementing all kinds of dashboards in the system and logistic reports that give the possibility of checking and confirming the delivery time, production date and the current place of the goods ‘in transit’ are also important for effective communication and information flow between the automotive supplier and the recipient – vehicle manufacturer.

Labels in the automotive industry

Besides document transmission standards, customers of automotive manufacturers must adapt to the requirements related to the way products are packaged and labeled. It happens that the same component, depending on the recipient, has a different name, requires a different marking, and the label on the final product should be designed in a very individualized way.

So let us imagine a company producing, for example, fuel pumps or seat belt pretensioners, delivering its product to various recipients. Depending on the customer, the product label must look completely different. This entails an appropriate method of warehouse and storage management – when completing an order for a customer, it is important to know which shelf the products and components for a given customer are on.

A product with identical technical parameters with an incorrect label is not the same product.

But big vehicle manufacturers have the quality standards that they impose on their suppliers. One component, such as the remove fuel pump, is most often produced by several suppliers to reduce business risk. By following their standards, each supplier must deliver an identical product – both technically and visually. Adherence to these standards is often a condition for continuing cooperation.

Besides labels, packaging standards are also important – each manufacturer has its requirements. Single packing, in a certain number of pieces – packing boxes into boxes and, of course, labeling boxes are rules that should be respected on an equal footing with others. For a component manufacturer, supplying its products to various automotive companies – there is a need to plan production, manage to package, and its quality.

Cost optimization

The necessity to adapt to various standards imposed by customers requires monitoring logistic costs related, in particular, to the production of labels and packaging. Many manufacturers of automotive components pay attention to the fact that the implemented ERP system can model processes by the Lean Manufacturing and Kanban philosophy to minimize waste and cut unnecessary operations and procedures during the production process.

The flexibility of the ERP solution, its scalability understood as the possibility of using various types of production and expansion taking into account often different and very individual customer requirements is an important criterion for choosing the best solution

Choosing the right partner

Even the best IT solution that allows the most accurate adaptation to all requirements and limitations is not enough if the company undertaking its implementation does not know the business conditions and the specifics of the operation of manufacturing companies in the automotive industry.

Knowledge of EDI data exchange standards in Automotive, warranty processes, and principles of cooperation with vehicle manufacturers is obligatory confirmed by experience in cooperation, firstly, with other component manufacturers, and secondly with their recipients – automotive giants.

As VisiON Architect. SolutiON Maker, Hicron has all the necessary skills and knowledge to support production companies. For nearly 15 years we have been cooperating with companies from the automotive industry around the world: importers, dealers, manufacturers of vehicles, and components. As Vision Maker, we create system architectures, design software, and translate needs and innovations into specific IT solutions.

By implementing IT projects related to the implementation and development of industry-specific solutions for the automotive industry, we help them optimize logistics, production, and sales processes, bringing them closer to achieving global development goals. Distinguished by the SAP manufacturer with the SAP Recognized Expertise in Automotive title, as a Solution Maker, we specialize in the implementation of SAP solutions for the automotive industry, which represent the highest management standards in this industry.

Want to learn more? Contact our consultant!